A known machine manufacturer in the food industry needed to add the capability for their customers to be able to make their own Machine Recipes.

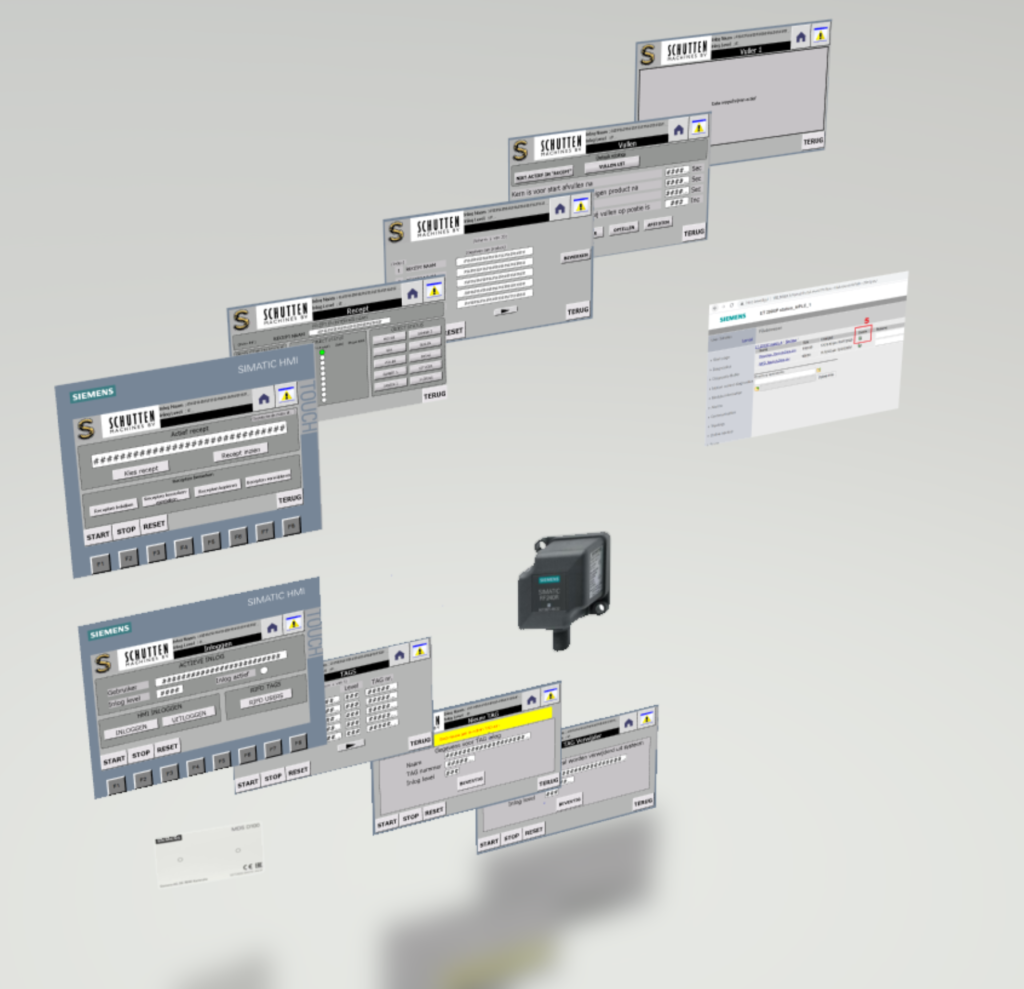

The challenge in this project was that the software had to be transferable to other projects, so that it could be used in a Siemens 1200 and 1500 CPU with TP as well as Confort HMI panels and that the data would be retained if an error was made.

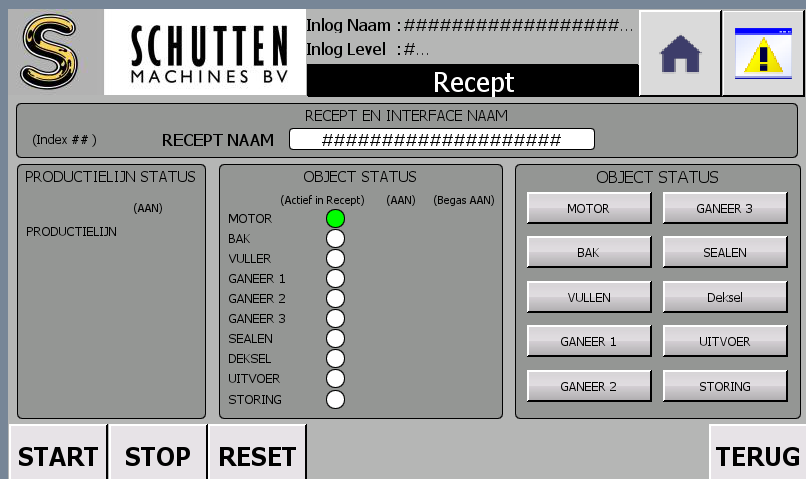

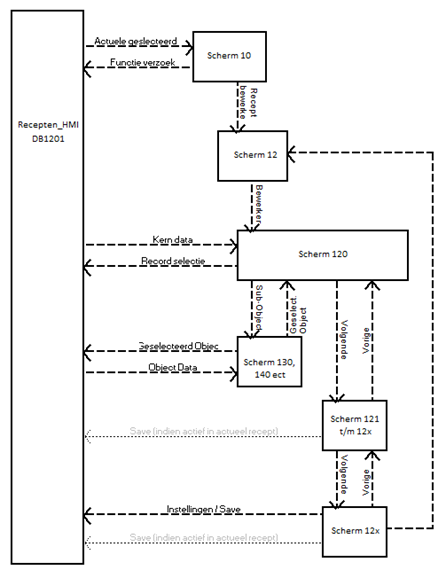

The request was for 100 recipes but had been setup in a way that the data was not one long data stream but divided into subsections for the different machine sections.

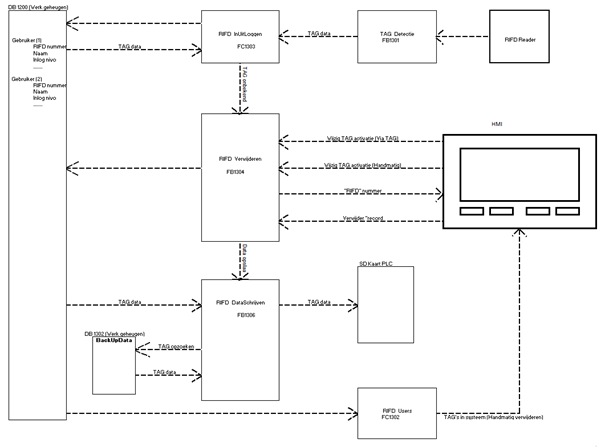

The request for the RFID login required it to be possible for at least 25 login identities where the data of the user can be added. It was also necessary to be able to add new RFID cards into the machine.

The solution we designed for the customer was a modular software solution that runs at a 1200 as well as a 1500 PLC from Siemens. The machine buildup settings were done in UDTs, with a standard interface to the HMI and to the PLC where the actual machine operating instructions are running.

For the HMI we created a couple of standard faceplates that automatically handle the interface between the HMI and PLC, where only the data has to be filled in for what is needed for the project.

To ensure that there is no data loss in case of an error we made it possible to write the data to the memory card of the PLC when there is a data change made in one of the “Recipes” or when there is data change in one of the RFID user logins.

This data is retrieved when there is a PLC restart. We also added the option that it is possible to backup and retrieve the data from the PLC via the interface.